In the modern manufacturing era, efficiency, precision, and optimization are key drivers of success. One crucial aspect that ensures these factors align is Machine Planning. Whether in small-scale industries or large production plants, businesses across Fashion Manufacturing rely on machine planning to optimize their workflows, reduce downtime, and maximize productivity.

Whether it’s scheduling machines in a factory, managing operations, or streamlining production processes, effective machine planning ensures that resources are used efficiently and operations run smoothly.

But what exactly is machine planning, and why is it so crucial? Let’s find out.

What is Machine Planning?

Machine planning refers to the process of organizing, scheduling, and optimizing the use of machines in a production or automation environment. It involves determining what tasks a machine will perform, when it will perform them, and how resources will be allocated to maximize efficiency.

Hence, analysing the production requirements, scheduling machine operations, and ensuring minimal wastage of resources such as raw materials, time, and labour

This can include everything from planning production sequences on an assembly line to programming industrial robots for autonomous operations. Modern Machine planning often integrates Business Intelligence and data analytics to enhance decision-making, minimize downtime, and improve overall performance.

How does FashionNX Aid Machine Planning?

In FashionNX, the Machine Planning module provides a user-friendly interface that helps manufacturers efficiently schedule machines, allocate resources, and track production progress in real time.

It improves machine planning through optimized machine utilization, ensuring resources are used efficiently. It provides a comprehensive calendar that offers a clear view of ongoing manufacturing activities, enabling better scheduling and coordination. With production planning and control features, it streamlines workflows and minimizes downtime.

Additionally, if an order gets cancelled, the system automatically adjusts the future manufacturing calendar, preventing resource wastage and ensuring seamless operations.

Today we dive into how users can access Machine Planning in FashionNX and use it to their advantage.

Machine Planning in FashionNX

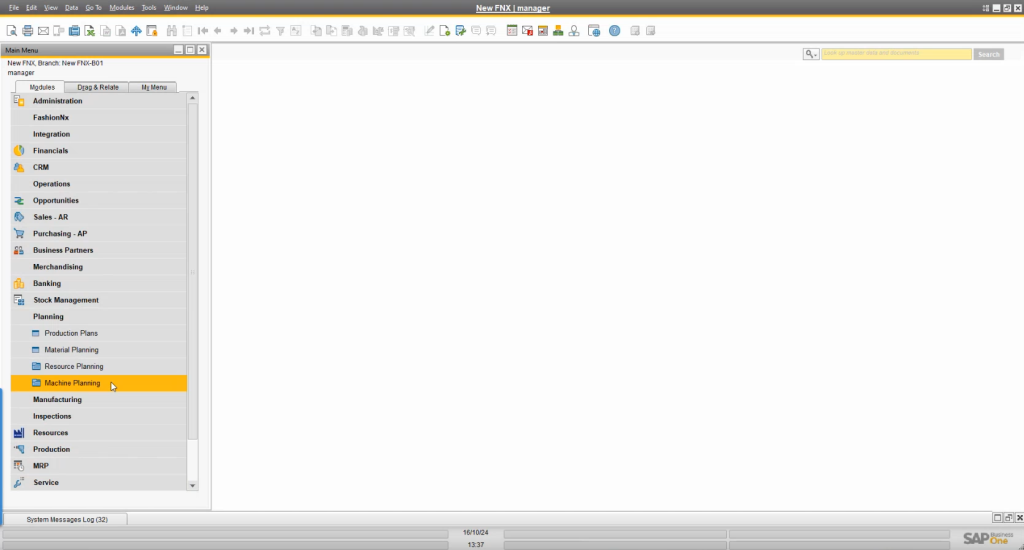

Accessing Machine Planning

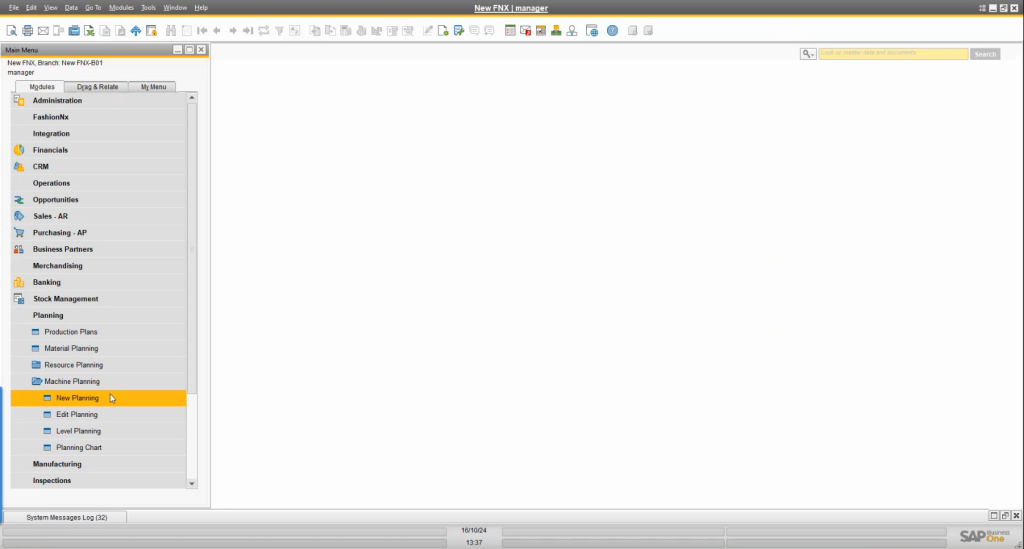

To access the Machine Planning module in FashionNX, users need to navigate to the Main Menu panel and select Planning > Machine Planning

This will direct them to the Machine Planning interface, where they can initiate a new plan by clicking on the New Planning option

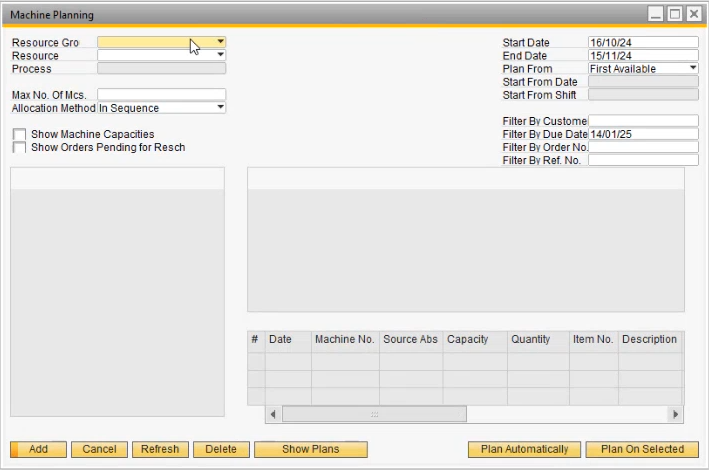

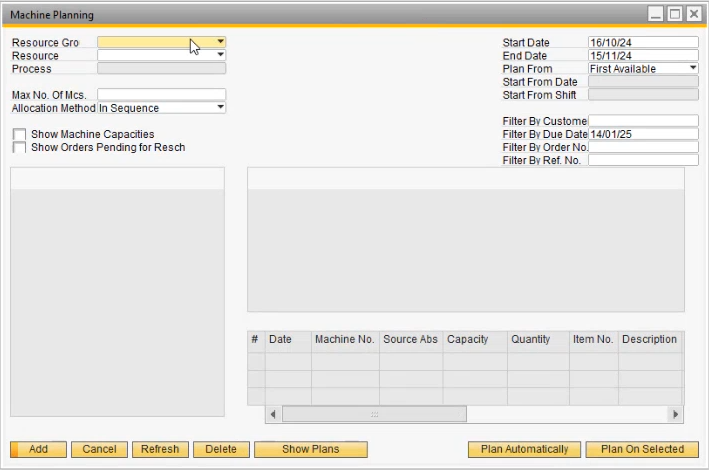

Upon selection, the Machine Planning window will open, providing users with a comprehensive view of available resources, machine capacities, and scheduling options

This window serves as the central hub for managing and optimizing machine utilization, ensuring a streamlined and efficient production workflow.

Understanding the Machine Planning Window

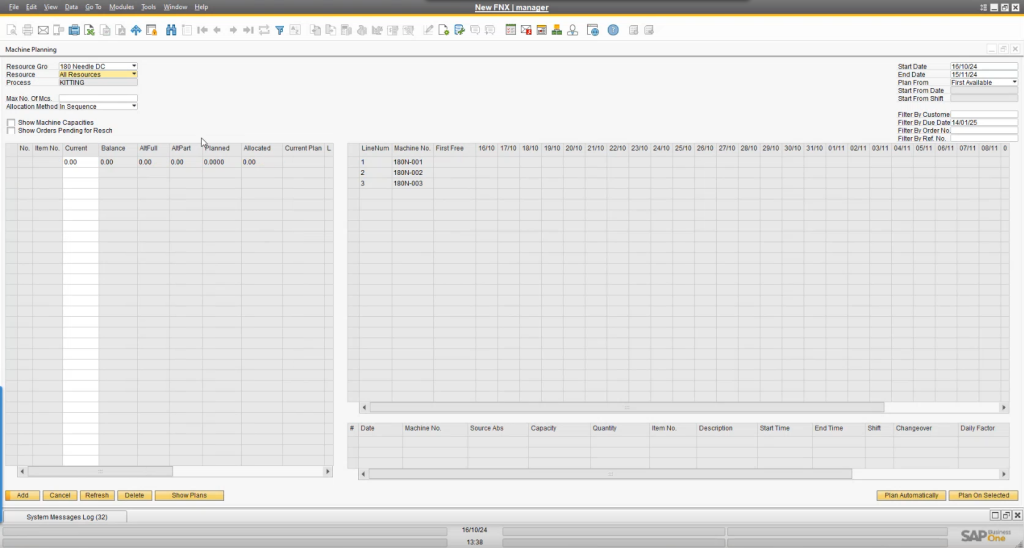

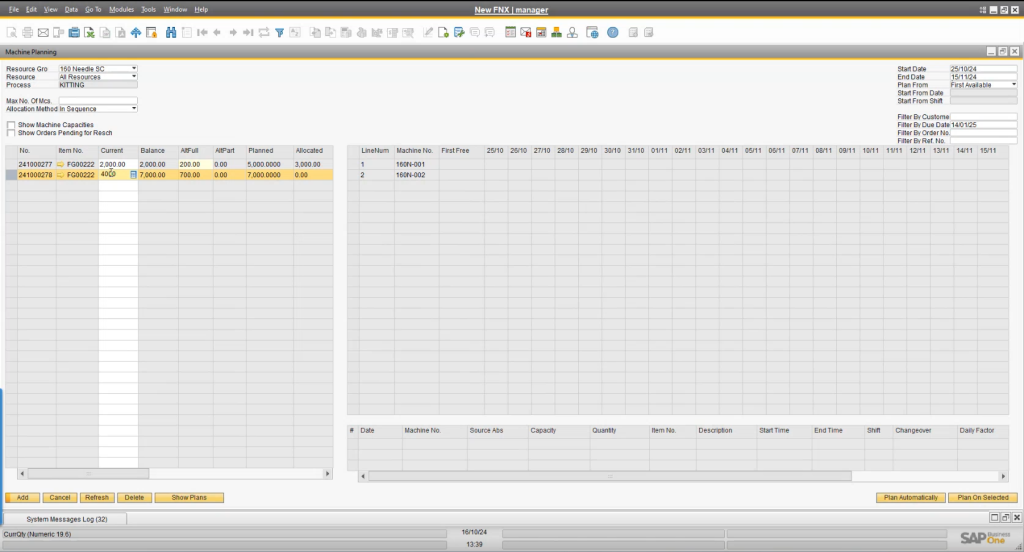

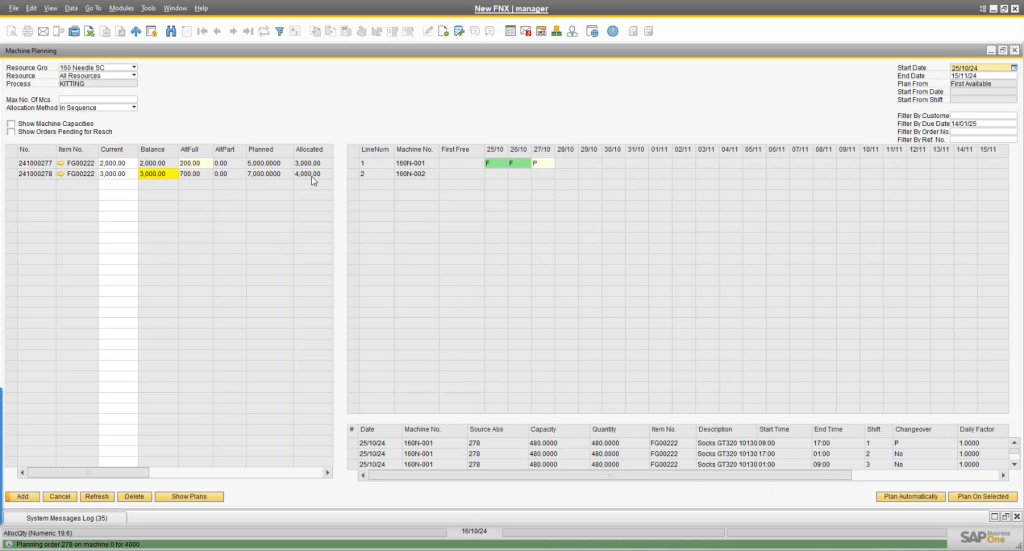

In the Machine Planning window users will find: Resource Gro (Resource Group), Resource, Process, Max No. Of Mcs., and Allocation Method fields on the top left and Start Date, End Date, Plan From, Start From Date, Start From Shift, Filter By Customer, Filter By Due Date, Filter By Order No., and Filter By Ref. No. fields on the top right.

Additional Features include the checkboxes for Show Machine Capacities and Show Orders for Resch below the top left fields.

At the bottom there are buttons:

Left: Add, Cancel, Refresh, Delete, Show Plans

Right: Plan Automatically, Plan On Selected

Starting Machine Planning

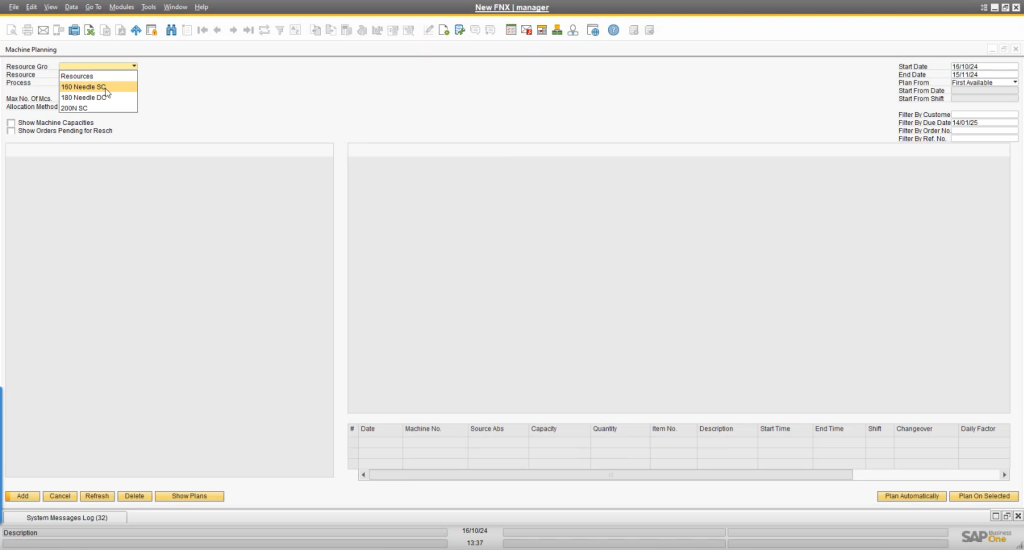

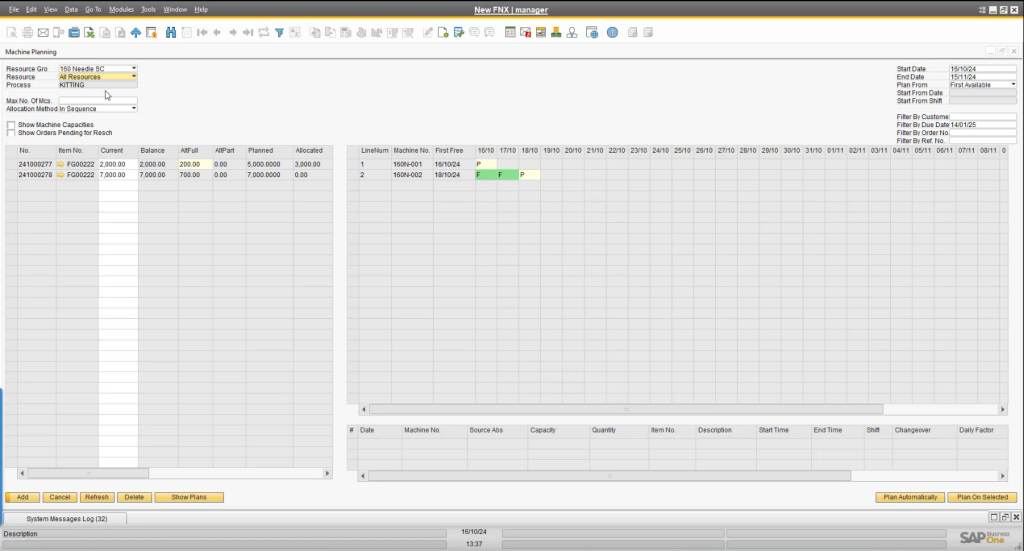

To begin Machine Planning, users must first select the Resource Group by clicking on the Resource Gro dropdown menu. Here, they will see options such as 160 Needle SC, 180 Needle DC, and 200N SC. This example will showcase a typical machine plan for Knitting.

Users can then choose the appropriate resource—160 Needle SC, for instance. Upon selection, the Resource field automatically updates to All Resources, and the Process field is set to Knitting

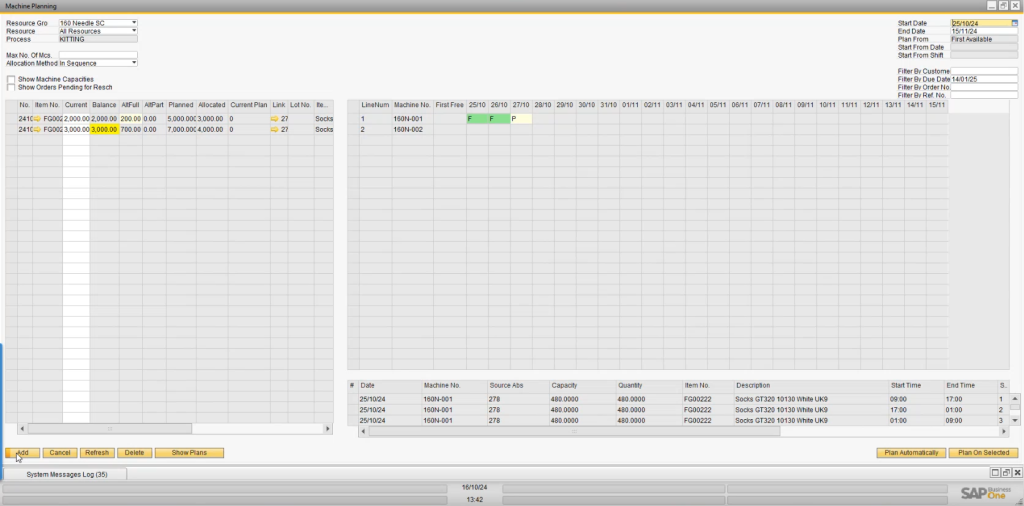

Below this selection, a table displays key details such as No., Item No., Current, Balance, AltFull, AltPart, Planned, and Allocated quantities. The system auto-fills these fields based on existing orders, while unplanned orders are also listed. To the right, another table displays available machines based on the selected resource.

For example, selecting 180 Needle DC in the Resource Gro field updates the machine table, where the LineNum column lists 1, 2, and 3, and the Machine No. column updates to 180N-001, 180N-002, and 180N-003

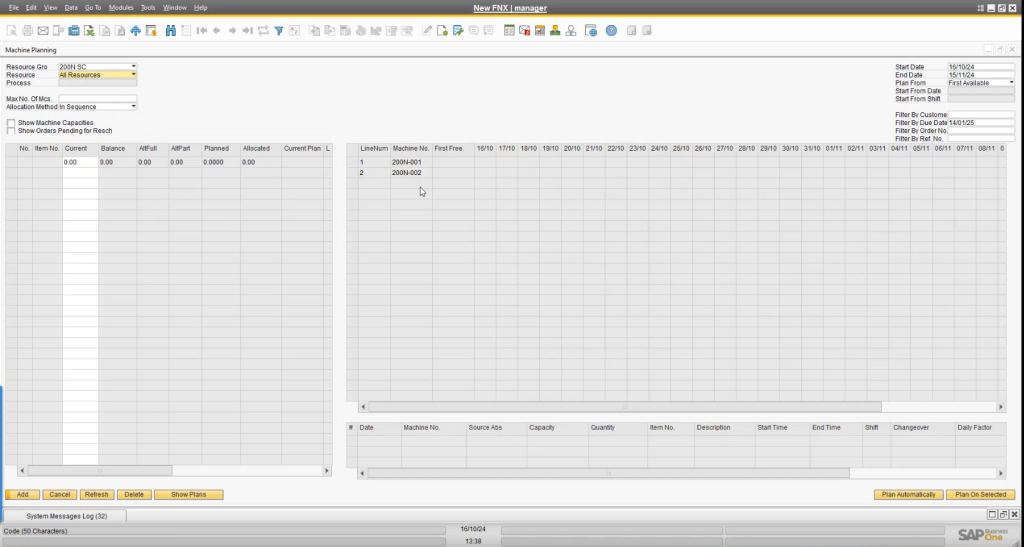

Similarly, when 200N SC is chosen in Resource Gro, the LineNum and Machine No. columns update accordingly to 1 & 2 and 200N-001 & 200N-002, respectively

Setting Production Dates and Quantities

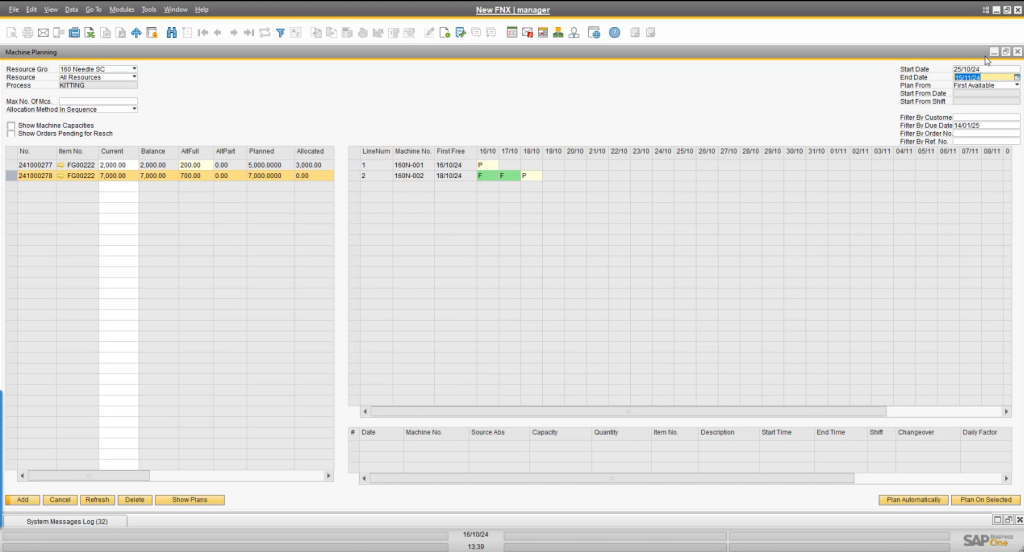

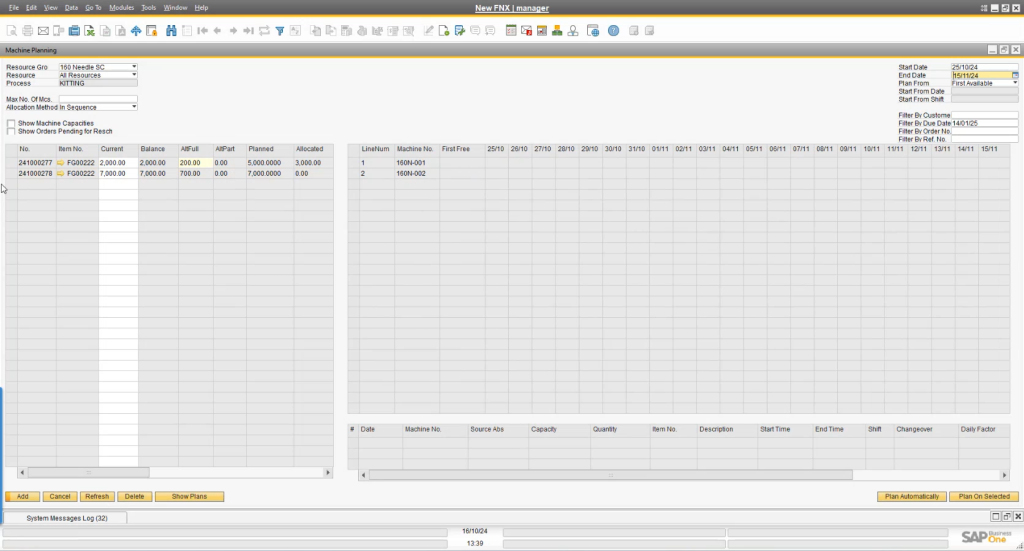

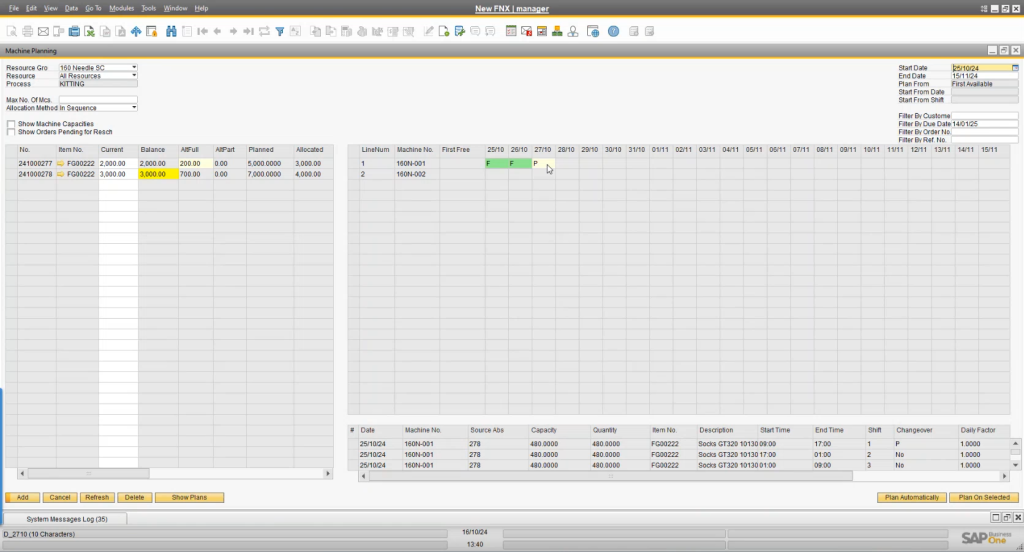

Users can easily set the production start and end dates by clicking on the Start Date and End Date fields and selecting the required dates—25/10/24 and 15/11/24, in this example

Once selected, the system automatically updates these dates in the First Free row of the machine table.

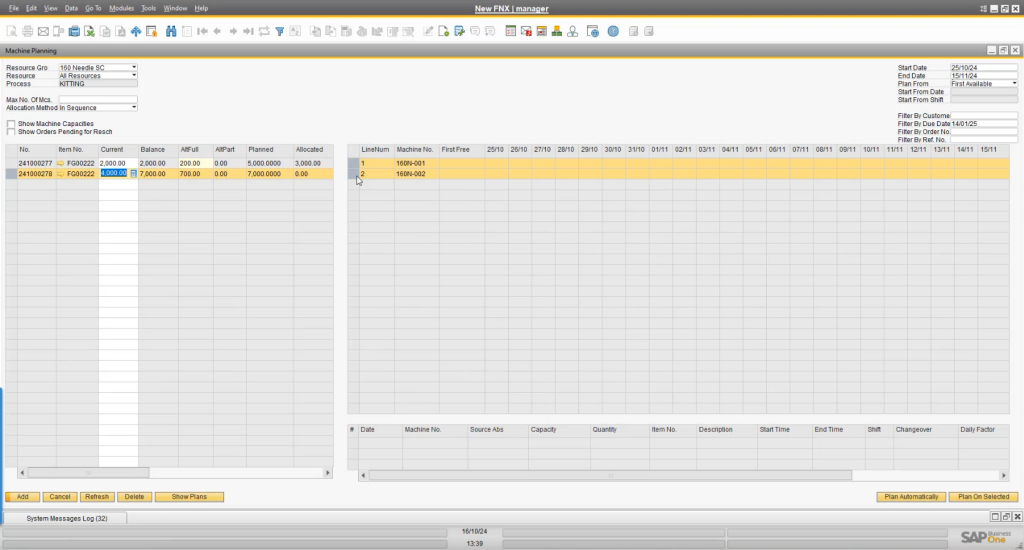

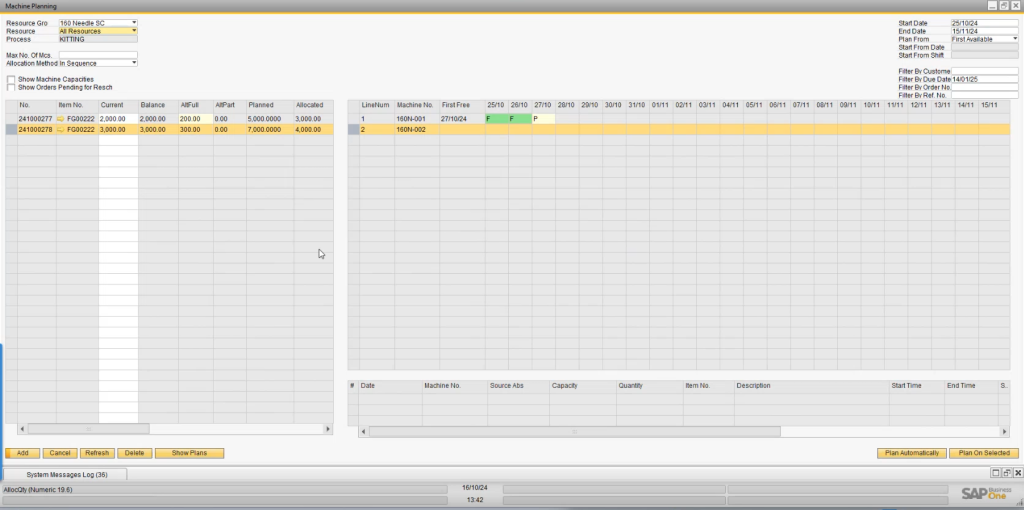

After setting the dates, users can proceed to plan the order quantity. For instance, the Current column of the second order initially shows 7,000 units

If a partial quantity needs to be planned, users can simply click on the quantity field and update it to the desired value—4,000 in this case

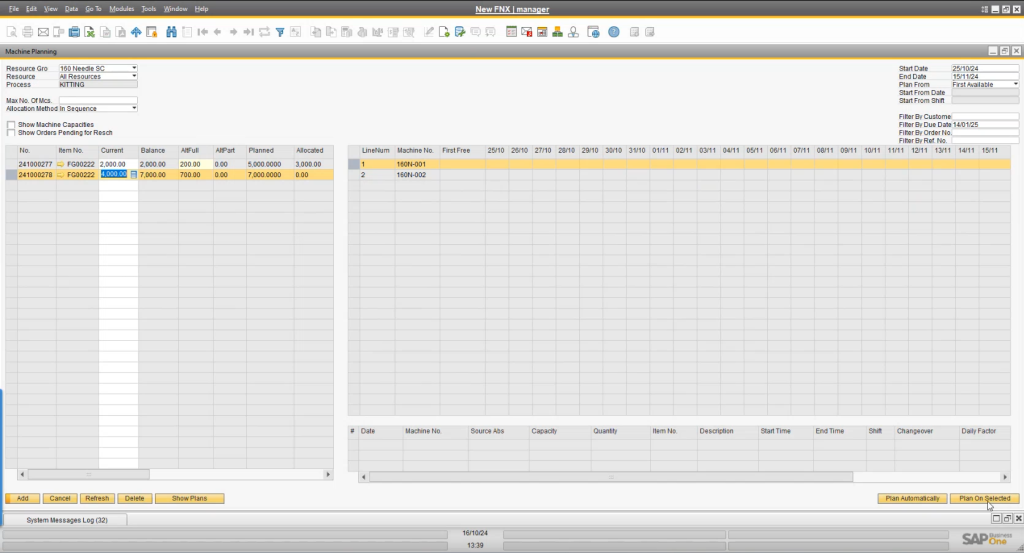

Next, users can assign the order to specific machines. Multiple machines can be selected for the task as needed

Once the selection is made, clicking on the Plan On Selected button in the bottom right finalizes the planning

Generating and Viewing Machine Plans

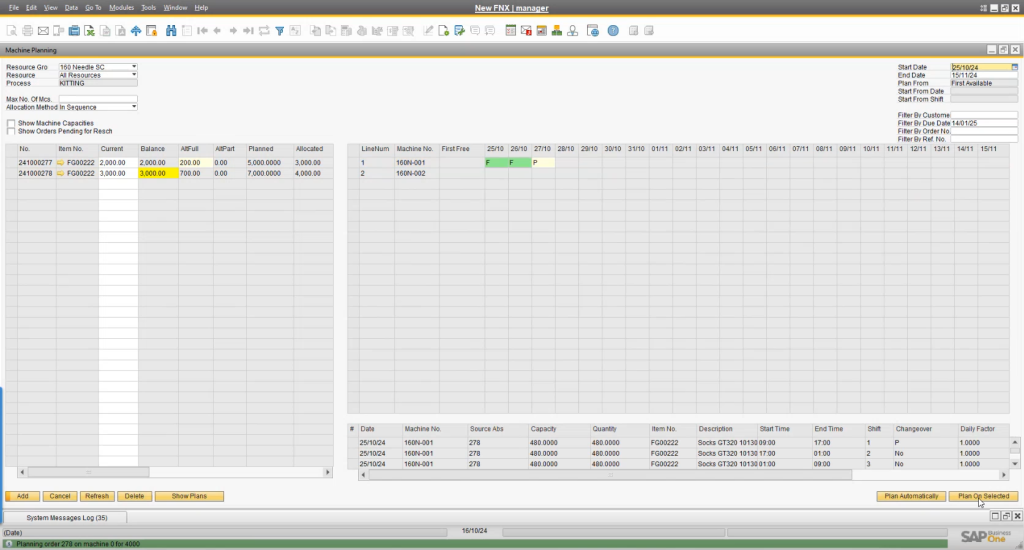

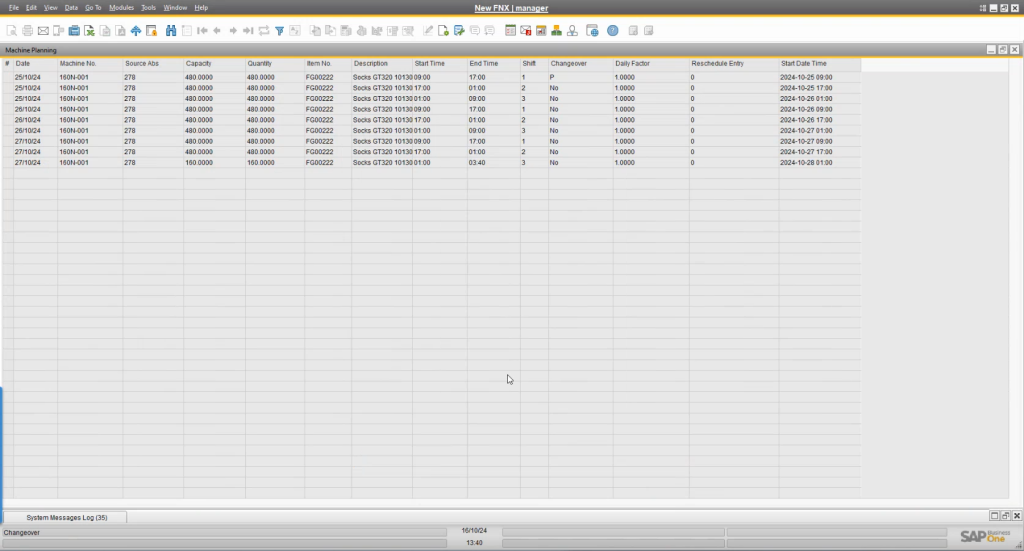

Once the planning is complete, the table below the machine table automatically populates with detailed information, including #, Date, Machine No., Source Abs, Capacity, Quantity, Item No., Description, Start Time, End Time, Shift, Changeover, Daily Factor, and more

Additionally, the second order in the order table gets updated—specifically, the Balance column reflects 3000, while the Allocated column updates to 4000

The machine utilization status is also displayed: for 25/10 and 26/10 as Full. The machines are fully utilized, marked by an “F” highlighted in Green, while on 27/10, utilization is partial, denoted by a “P” highlighted in Light Yellow

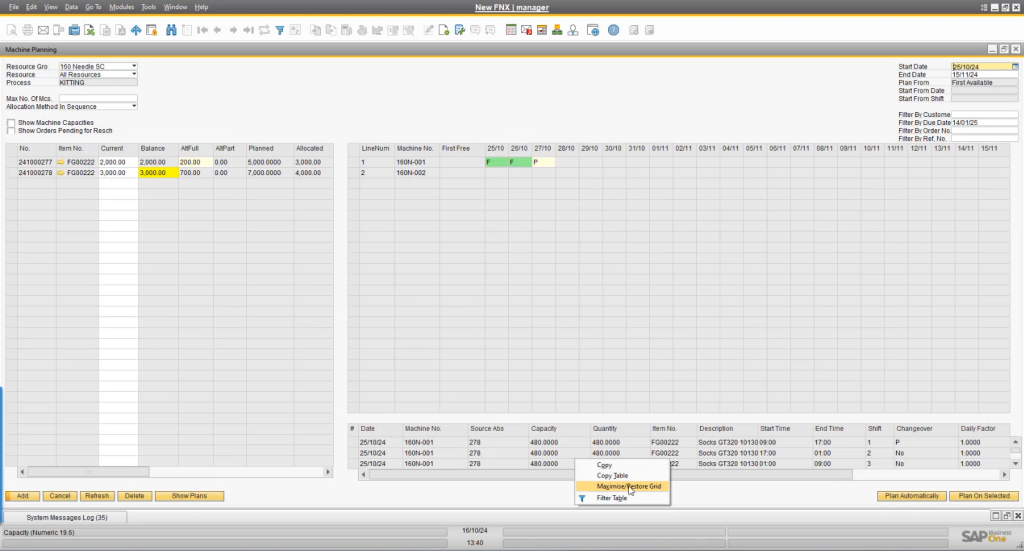

Users can expand the Planning table by right-clicking and selecting “Maximize/Resize Grid”, allowing for a clearer view of the scheduled plan spanning 25/10 to 27/10

This will expand the Machine Planning window, showcasing the plan for the three days – from 25/10 to 27/10 In this manner, users can generate a Machine Plan.

Once the machine plan is finalized, users can save and add this plan by clicking the “Add” button at the bottom left of the Machine Planning window

To view the plan for a specific order, users simply need to select the order and click on the “Show Plans” button, which will display the full details of the selected plan

Editing, Assigning Operators, and Rescheduling Plans

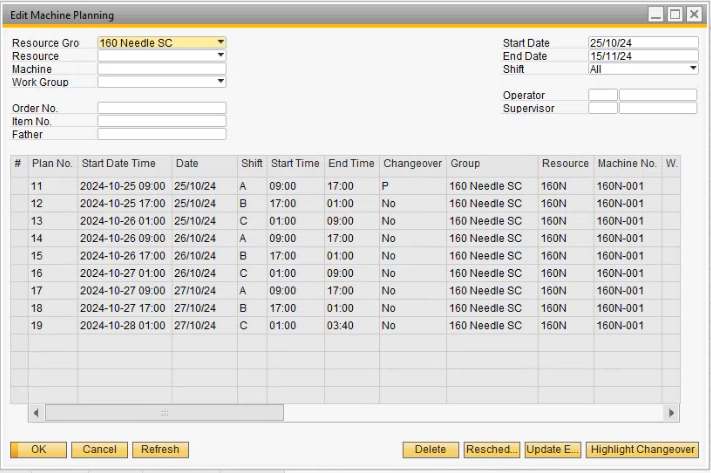

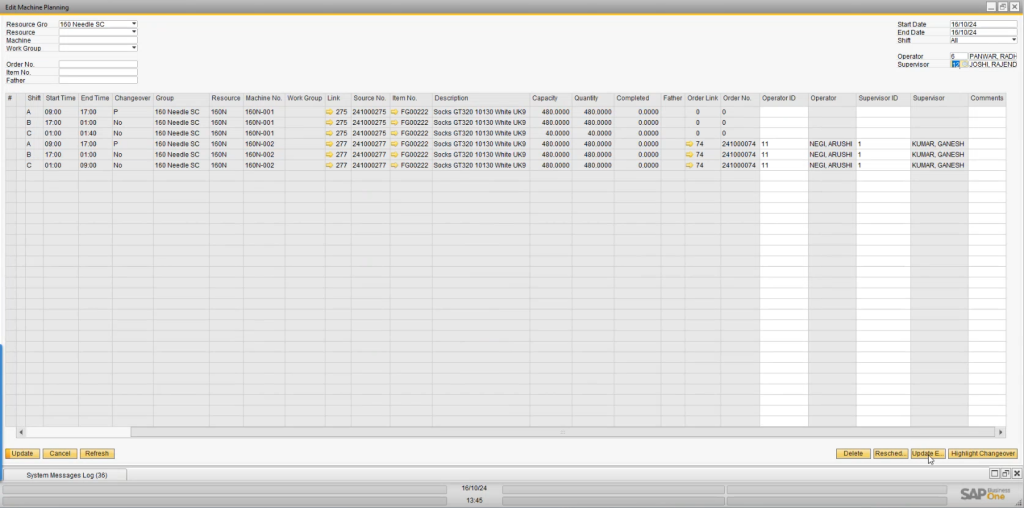

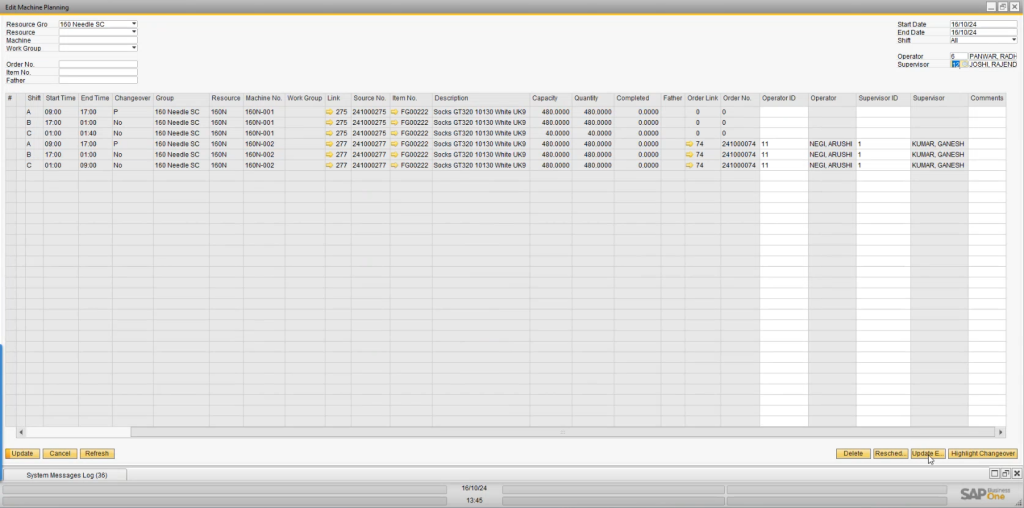

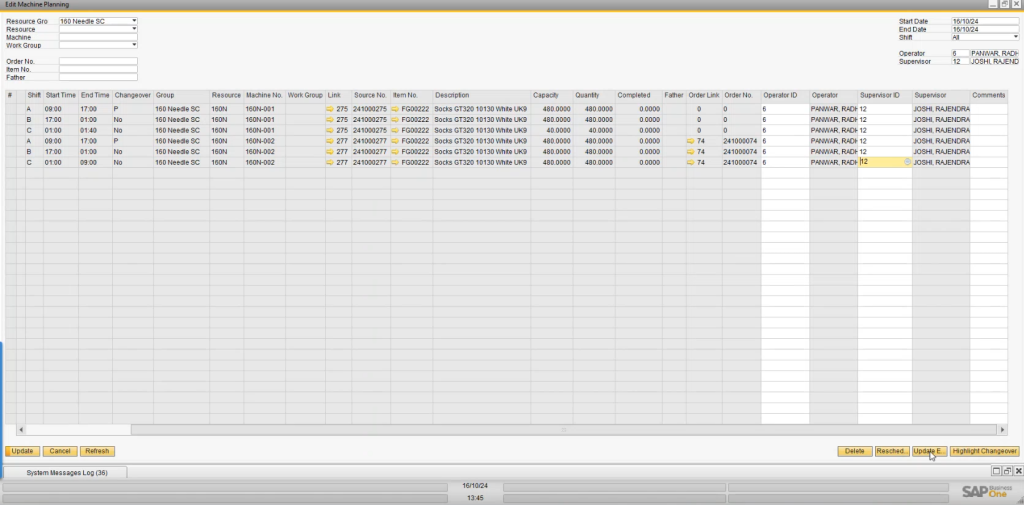

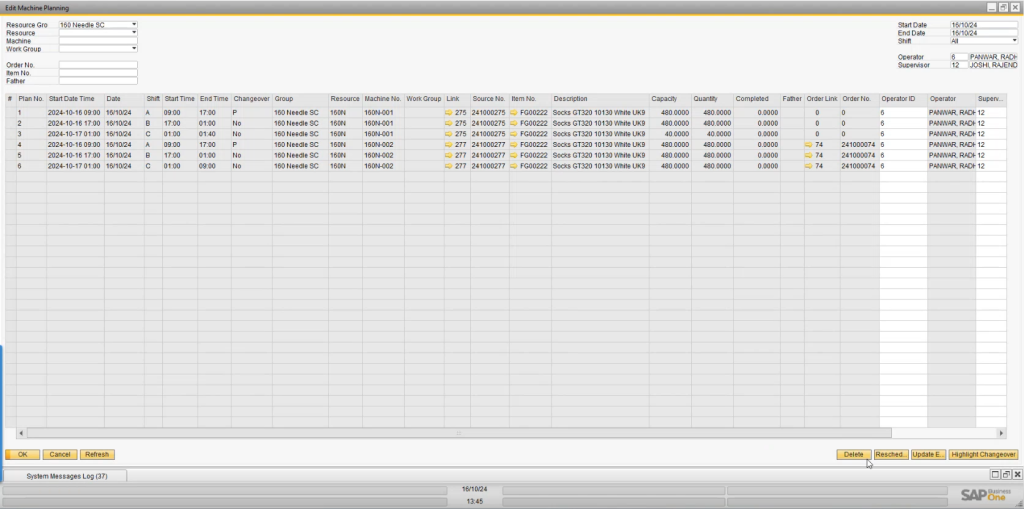

Clicking on Show Plans opens the Edit Machine Planning window, where the selected order is displayed in full detail

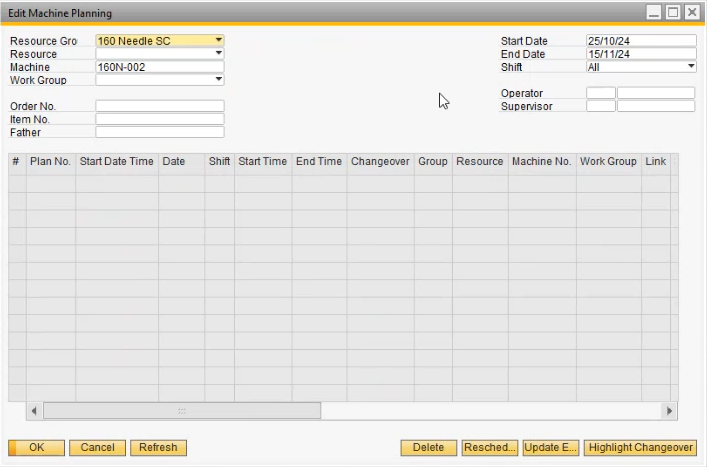

If a machine without an existing plan is selected, the same window will open, but without any pre-filled plan details

Users can also select a machine with an existing plan and click Show Plans to view all associated details

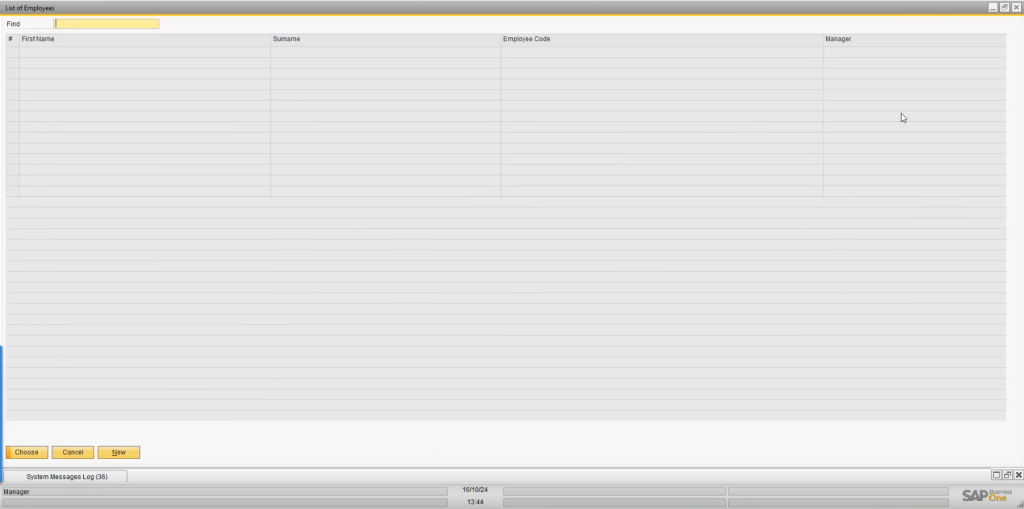

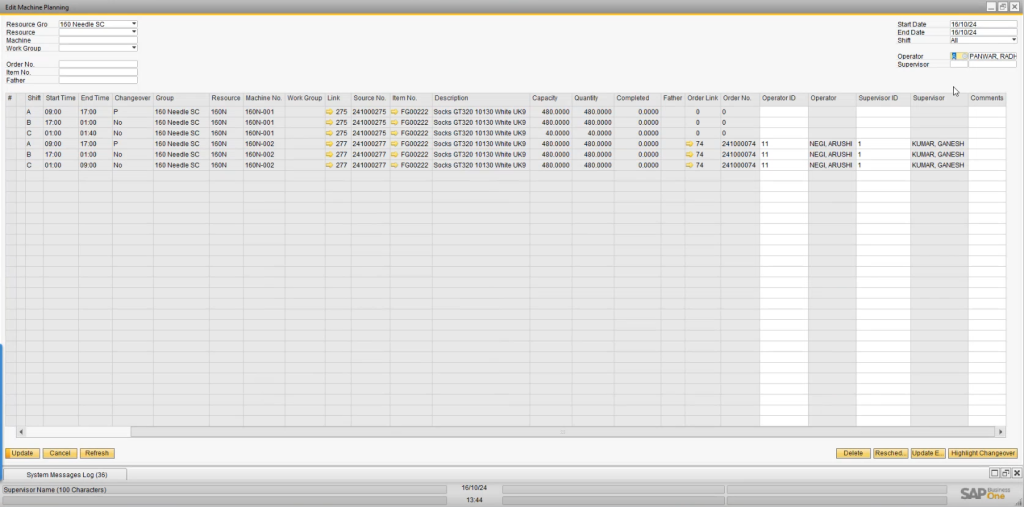

Additionally, users can assign/update operators in the Operator field at the top right of the Edit Machine Planning window. Clicking on this field opens the List of Employees window, allowing users to select an operator .

Once an employee is chosen, their name appears in the Operator field .

This process can be repeated for each machine.

After assigning operators, users simply need to click the Update button, which is the third button on the bottom right

Once updated, all assigned operator names will be visible in the Operator column of the plan table

Moreover, users have the flexibility to delete or reschedule machine plans using the Delete and Reschedule buttons located in the bottom right corner of the Edit Machine Planning window

Conclusion

Effective Machine Planning is the backbone of any efficient manufacturing process, ensuring optimal resource utilization, minimized downtime, and streamlined operations. With FashionNX’s Machine Planning module, users can effortlessly schedule machines, allocate resources, and track production in real time—all through a user-friendly and intuitive interface.

From selecting resources and scheduling production to assigning operators and optimizing machine utilization, the module offers a comprehensive solution to simplify complex planning tasks. The ability to edit, reschedule, and manage machine workloads dynamically further enhances efficiency, enabling manufacturers to adapt quickly to changing demands.

By leveraging FashionNX’s powerful Machine Planning capabilities, businesses can achieve greater precision, reduced waste, and increased productivity—leading to smoother operations and enhanced profitability. Whether for small-scale production or large industrial setups, implementing structured machine planning is a game-changer for manufacturing success.