Your Key to Achieving Seamless Production & Sales Efficiency

In the fast-paced world of apparel, footwear, and fashion, tracking production & sales processes, meeting deadlines, and maintaining communication across departments are essential to success.

However, managing multiple orders, tracking progress, and ensuring deadlines are met can be challenging. Where timelines are tight and numerous teams work on different aspects of production, having an effective method of tracking every step is critical.

That’s where FashionNX’s Time & Action (T&A) Plans come into play.

Offer a robust solution to achieving

Production Efficiency.

What is FashionNx’s Time & Action Plan Feature?

FashionNX’s Time & Action (T&A) Plans are designed to simplify tracking of the various processes involved in production, from the order creation to its completion. Time & Action (TNA) Plans provide businesses with a structured framework to track the progress of a product from the initial stages of sampling and design through to the final delivery.

They allow businesses to plan, monitor, and manage each phase of the production process efficiently. Whether it’s creating and completing sample orders, managing raw material needs, or setting accurate delivery dates, TNA plans to ensure that every action is tracked and completed on time.

These plans help businesses stay organized, track progress, and ensure the timely completion of all tasks required to fulfill orders.

Time & Action Plan Templates

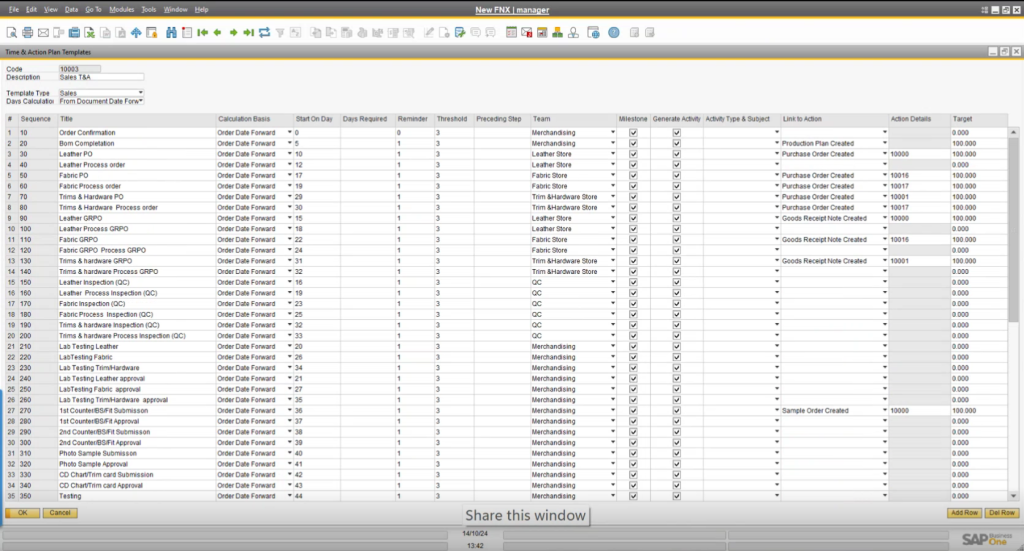

Businesses can find various Time & Action Plan Templates available for them of the different production & sales scenarios involved, from Order Confirmation to Shipment.

Around 67 Templates are currently available in the Template Section of the Time & Action Plan. All 67 processes can be used in a single T&A plan if needed.

The Time & Action Plans can be named as desired by the businesses.

Creating a Time & Action Plan

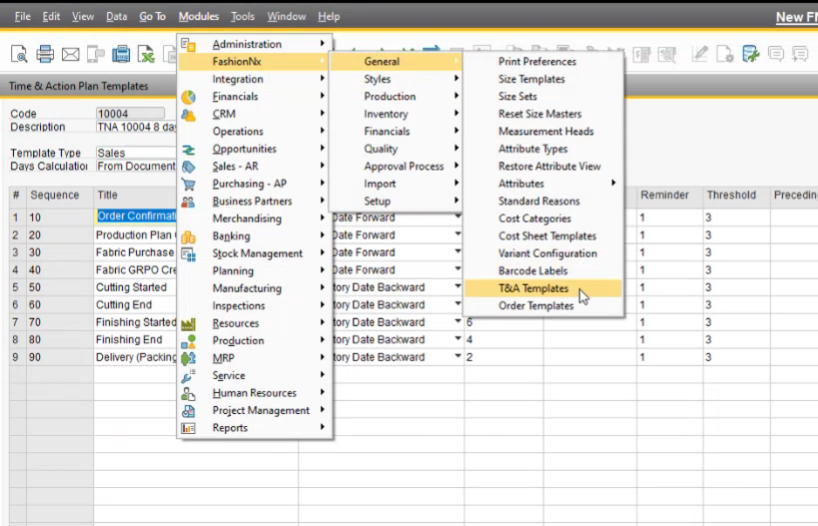

The first step to creating a T&A Plan is to click Module > FashionNx > General > T&A Templates.

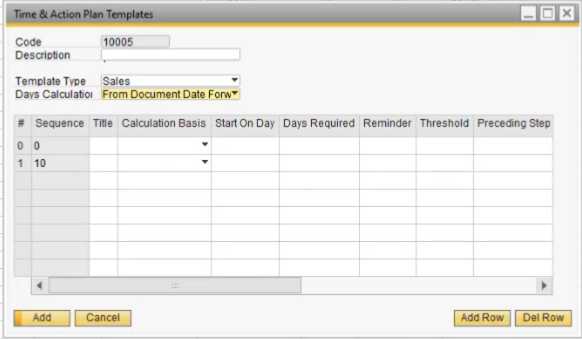

Once the plan template opens, users can input Custom Name for the Processes in the “Description” Section.

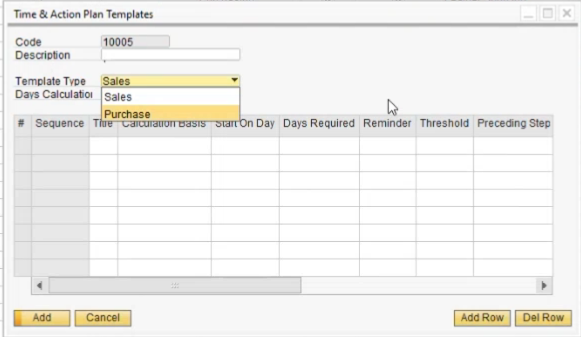

Users can define the type of template in the “Template Type” in the box. Two Types are Available – “Sales & Purchase”.

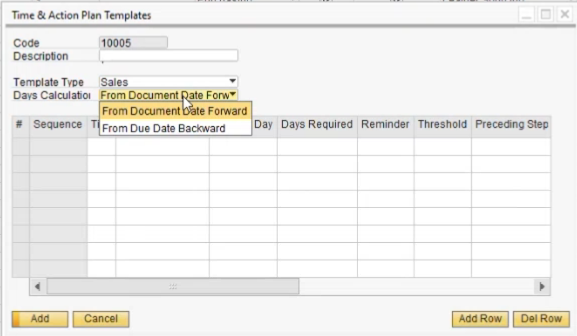

Next, in the “Days Calculation” section, users can select between two options – “From Document Date Forward” & “From Due Date Backward”.

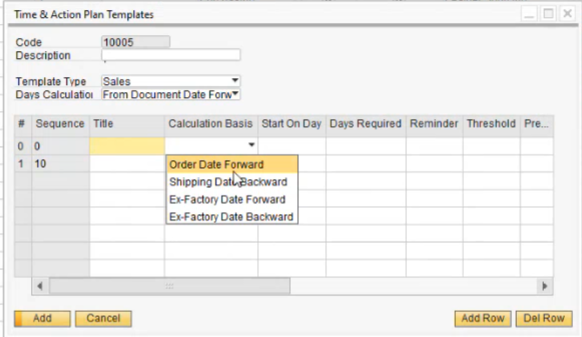

The Add Row button will allow you to add rows to your T&A plan and provide the sequence for the particular activity.

In the added rows, you can define the Title for the activity in the Title Column.

Then in the Calculation Basis Column, you can define based on which you can calculate the task dates. Four choices are available to define the Calculation Basis

- Order Date Forward

- Shipping Date Backward

- Ex-Factory Date Forward

- Ex-Factory Date Backward

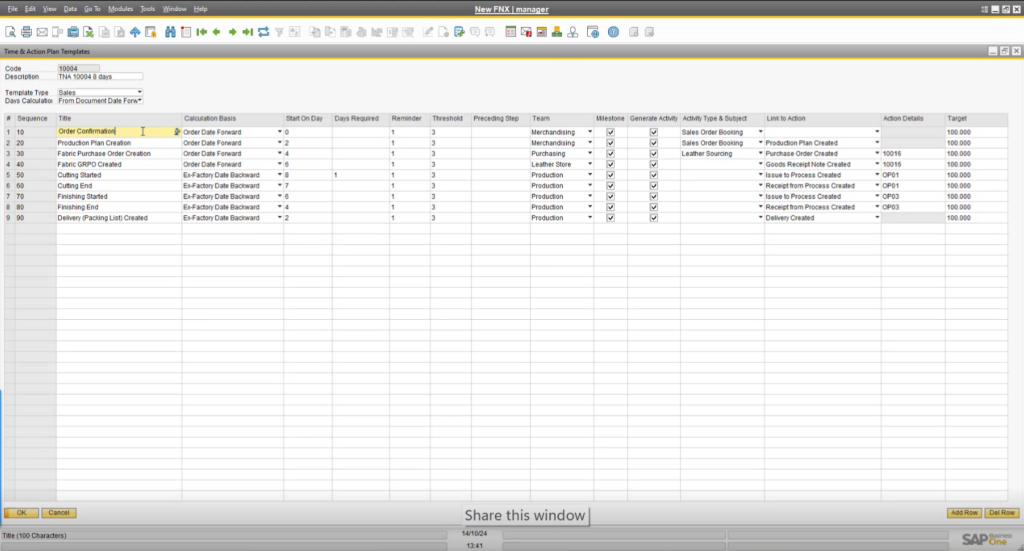

Layout of the Basic Time & Action Plan Template & Finalization

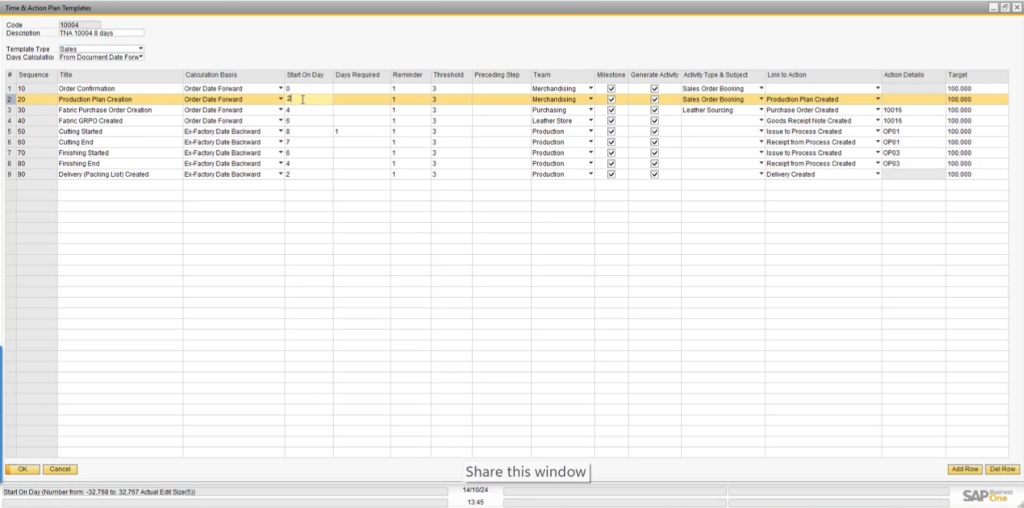

In the main T&A Plan Template window users can find the Title, Description, Template Type, and Days Calculation selected/defined by them.

Right below it, are rows consisting of “#”, “Sequence”, “Title”, “Calculation Basis”, “Start On Days”, “Days Required”, “Reminder”, “Threshold”, “Preceding Step”, “Team”, “Milestone”, “Generate Activity”, “Activity Time & Subject”, “Link to Action”, “Action Details”, and “Target”.

Once a Time & Action Template is finalized, it can be used to create a Time & Action Plan. Keep in mind that it is important to plan the quantity of the product to generate a Time & Action Plan.

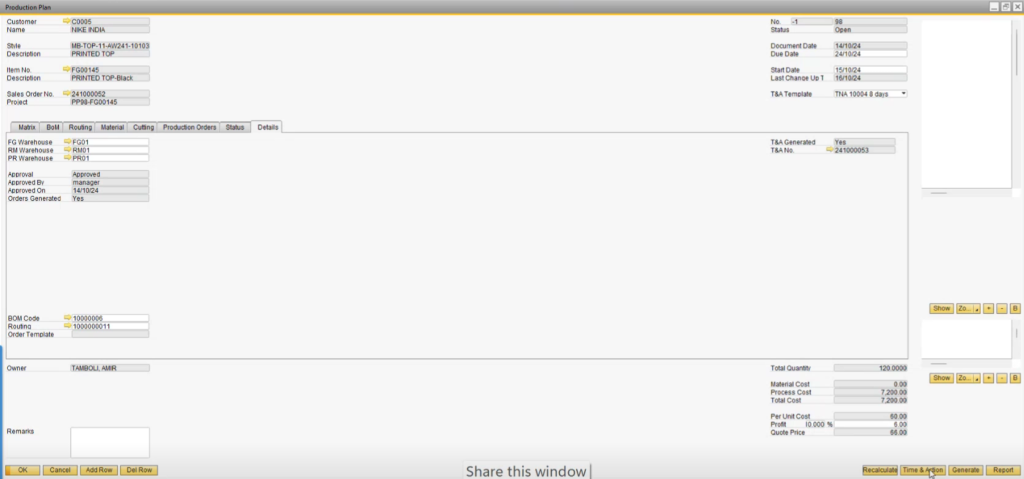

Users can also generate a T&A Plan directly from the Production Plan windows using the Time & Action button situated at the lower right side of the window.

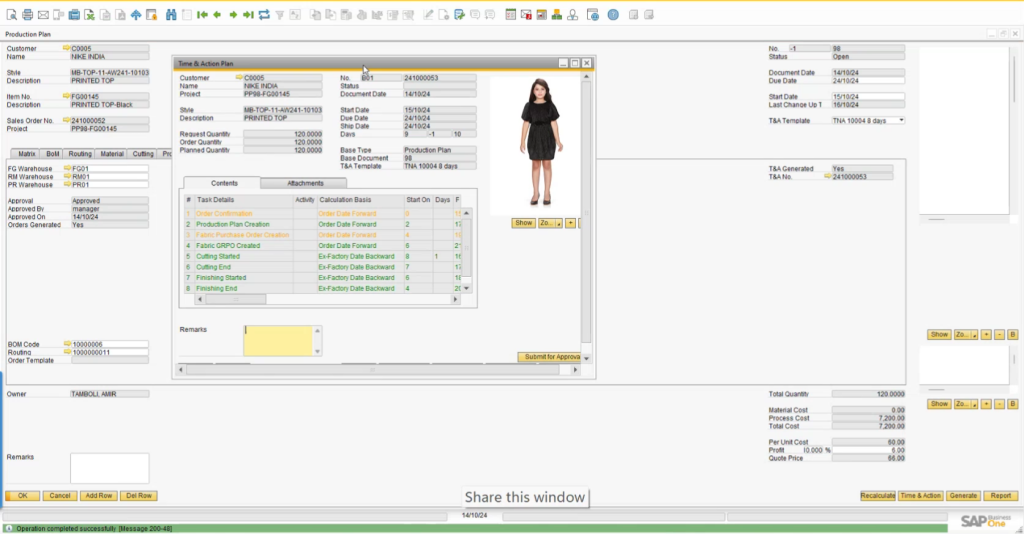

A Project will also be generated once you generate a T&A Plan which will be linked to it.

The generated T&A Plan will be based on the Document Date and Due Date a.k.a “Ex-Factory Date” dates selected in the Production Plan. The same dates will be reflected in the created T&A Plan.

Based on the dates, you can define the various aspects of the T&A Plan template

Users can define and add rows for Planned Start, Revised Start, Actual Start, Reminders, etc. Reminders can also be set for tasks in case of due dates and delays. In case of delays, relevant teams can be selected for the escalation notification.

Users can track every task and activity listed, individually, in the Time & Action Plan. Also, only the processes defined in the Routing Process can be a part of a T&A Plan.

Key Features of T&A Plans

Templates for Every Scenario

FashionNX, a comprehensive ERP platform known for its advanced features for Apparel, Footwear, & Accessories Manufacturing, offers 67 pre-defined templates for various production& sales scenarios, from order confirmation to shipment. This flexibility allows businesses to choose or customize the template that best fits their requirements.

Detailed Monitoring of Processes

Once the TNA plan is created, users can input various attributes for each task, such as planned start dates, revised start dates, and actual start dates. The plan also allows setting reminders and defining escalation paths if a task isn’t completed on time. These features ensure that there’s no ambiguity in the progress of production, as each process can be closely monitored.

Linking to Key Actions

Businesses can link key actions, such as the creation of purchase orders or sample receipts, directly into the TNA plans. This ensures that every aspect of the production cycle is connected and tracked seamlessly.

Escalation and Approval

In case of delays, the system can automatically send alerts to the relevant team members or escalate the issue to ensure quick resolution. Furthermore, finalized TNA plans can be sent for approval to department heads, ensuring that every step is well-coordinated across the organization.

Why T&A Plans Improve Operational Efficiency

T&A plans to offer a holistic view of production and sales activities, allowing businesses to streamline their processes and avoid unnecessary delays. The ability to pre-define tasks, assign responsibilities, and set timelines ensures that every team member knows what they need to do and when it needs to be done. This level of organization leads to fewer errors, smoother operations, and ultimately, a faster time-to-market.

For example, a common scenario might involve tracking whether raw materials have been ordered, or received, or if manual intervention is required from the merchandiser. This could prevent costly delays by ensuring follow-ups are done promptly. Additionally, the production team can plan efficiently, knowing exactly when they can expect materials and when to start different production phases.

Final Thoughts

In a world where timely delivery and meeting customer expectations can make or break a business, having a T&A plan provides a clear competitive advantage. It gives businesses the ability to plan accurately, monitor every step of the production process, and ensure that all tasks are completed on schedule.

Moreover, T&A plans enhance communication between teams, reduce the need for manual follow-ups, and ensure that the business operates in a well-organized, efficient manner.

By leveraging tools like FashionNX’s Time & Action functionality, Apparel, Footwear, & Accessories businesses can optimize their production and sales timelines and deliver products to their customers on time, every time—an essential factor in maintaining customer satisfaction and growing a business.